So I've been building a Prusa Mendel-design 3D printer. I've learned a lot in the process. This page is a collection of tips, tricks and ideas I've had while building my printer.

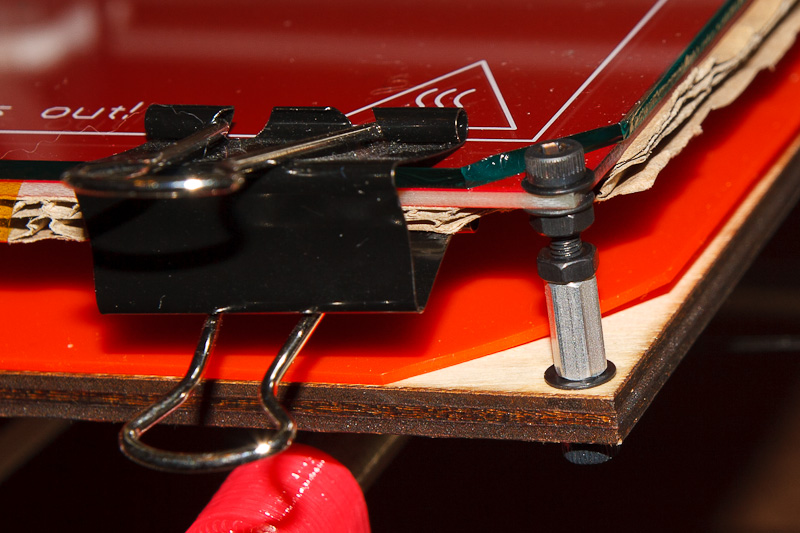

A lot of the Prusa Mendel directions I've seen called for ball-point pen springs over M3 screws used to adjust the bed height. I tried this, repeatedly, and it sucked...So I went back to my gearhead roots and decided to use a jam-nut type system to set and adjust the bed height. So far this bed-leveling system works incredibly well, allowing relatively easy dialing in of corner-to-corner height variance to under 0.03mm.

This setup assumes a wood bed base that's around 5mm thick and that you're mounting a PCB heater that's around 1.75mm thick.

You will need (for each corner):

On the bed side, place a washer on the 10mm M3 screw, pass the threaded end of the 10mm M3 screw through the bed base corner hole from the bottom up, place another washer on the 10mm M3 screw on top of the bed base and screw the 10mm standoff down tight on the 10mm M3 screw.

On the PCB heater side, put a washer on the 14mm M3 screw, run the screw through the PCB heater, put another washer on the screw on the underside of the PCB heater, then put both nuts on the 14mm M3 screw. Put the nuts somewhere in the middle of the screw for now.

Screw the 14mm M3 screw into the 10mm M3 standoff until the 14mm screw bottoms out, then back the screw out two full turns. This will provide you with around 1mm more of downward travel at each corner in case you need it, while keeping the overall bed height pretty low.

Once you've got the 14mm screw in where you think it's good, hold the 14mm screw still with an Allen wrench, tighten the nut closest to the 10mm standoff down to the standoff and secure the nut tightly against the standoff. This should lock the 14mm screw in its position relative to the standoff and 10mm screw.

Finally, tighten the other M3 nut against the underside of the PCB heater/washer.

Congratulations, you now have a very rigidly-mounted PCB heater that is height-adjustable from somewhere around 17mm above the bed base (from the top of the bed base to the underside of the PCB heater) to probably around 20mm above the bed base, more than enough to clear a corrugated-cardboard insulator/reflector and any fasteners with heads protruding above the bed base.

Hold the 14mm screw still with an Allen wrench, then back the nut off from the underside of the PCB heater. Continue holding the 14mm screw still, back the nut off from the 10mm standoff, adjust the height of the 14mm screw, then tighten the lower nut against the 10mm standoff. Finally tighten the top M3 nut against the underside of the PCB heater/washer.

When it's all said and done, it should look something like the following image.

Prusa Mendel frames are primarily composed of M8 threaded rod...Decently sturdy, but some of the handling practices I've seen in build directions are downright scary.

Don't ever grip the threaded rod with pliers or clamps placed on the threads directly. Screw on some M8 nuts and hold the rod via the M8 nuts with pliers or similar. You can fairly easily chew up the threads on the rod with pliers or clamps when gripping the threads directly, which will make life much more difficult than it should be down the road when you need to screw nuts pass the chewed-up threads.

When cutting your threaded rods, screw some nuts---or, ideally, some M8 thread dies---onto the rod on either side of where your cut will be. This gives you a place to clamp the rod when cutting, plus after you cut the rod and clean up the cut ends with a belt sander, grinder or file you can just twist the nut or die off the rod over the cut end, leaving behind good, clean threads that will make assembly much easier later.

Page created 20130622 16:34 CDT.

Page modified 20130722 23:38 CDT.

Comments? Suggestions? Hate mail? Send it to hemi@puresimplicity.net.